[lwptop]

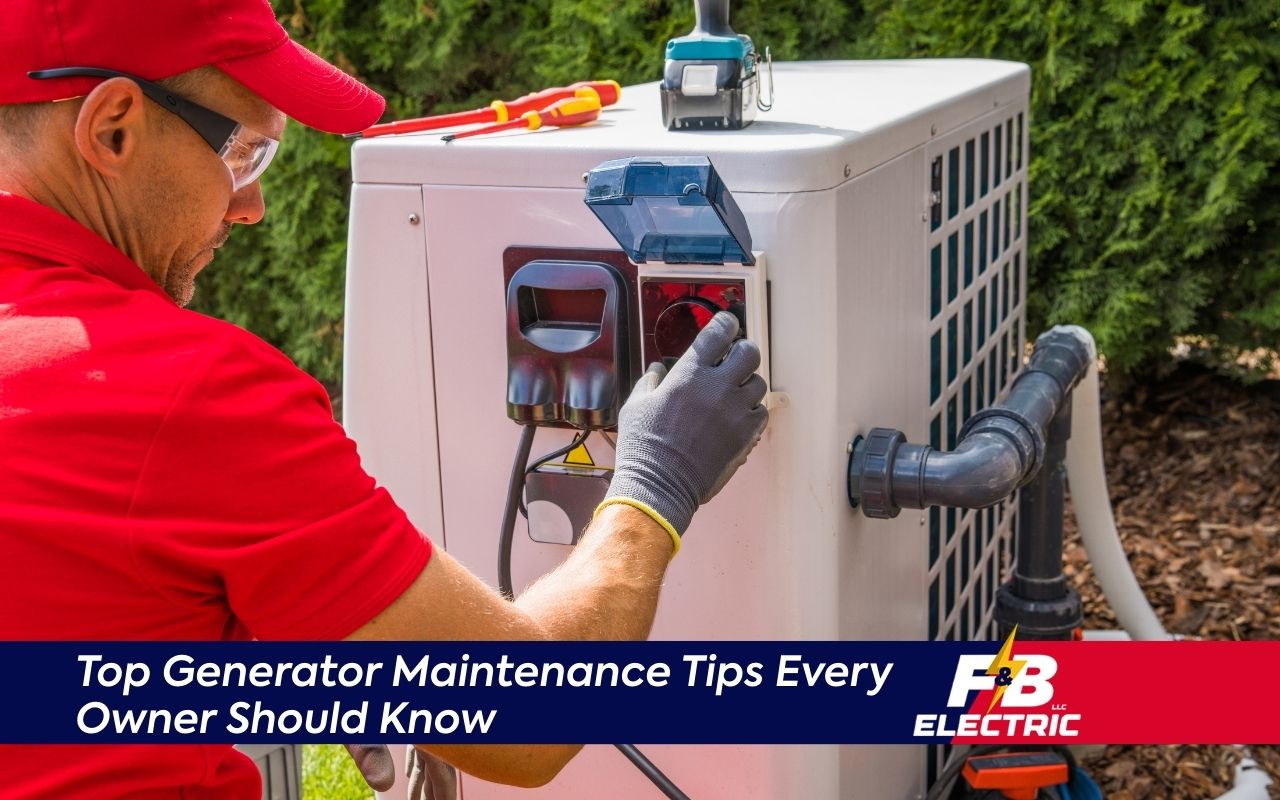

Owning a generator can be a lifesaver, especially when the power goes out unexpectedly. However, without proper care, even the most robust generators may fail. Understanding generator maintenance is critical for uninterrupted power during emergencies. Whether you recently had a generator installation for homes MD or are a seasoned owner, knowing generator maintenance tips can extend equipment life and prevent costly repairs. Let’s explore essential practices every owner should follow. Picture this: a storm hits, but your home stays illuminated because your well-maintained generator works flawlessly. These tips ensure your backup power source is reliable.

Importance of Generator Maintenance

Preventative maintenance saves money in the long run. Regular upkeep identifies minor issues before they escalate. Addressing problems early prolongs generator lifespan and ensures efficiency. Investing in routine maintenance avoids emergency repairs and extends equipment life.

Ensures reliable emergency power supply: A well-maintained generator delivers dependable power during grid failures or natural disasters. Following a schedule of inspections and servicing ensures seamless activation, protecting essential appliances, medical devices, and security systems. This reliability is critical for peace of mind.

Enhances safety for your household: Maintenance also guarantees safe operation. Faulty wiring, fuel leaks, or poor ventilation pose hazards such as fires or carbon monoxide. Routine checks mitigate these risks and create a secure home environment.

Regular Inspection Procedures

Systematic inspections are the backbone of effective generator maintenance. Create a checklist covering mechanical and electrical components for thorough service. Conduct inspections monthly and after severe weather events or long run times. Examine exterior panels, fuel lines, and exhaust systems for damage, corrosion, or leaks. Keep the casing clean for airflow. Check fluid levels, belts, hoses, and electrical connections inside the housing. Clean terminals and ensure wires are secure. Note unusual noises or vibrations during test runs. Document observations in a maintenance log to track trends. Following these inspection procedures reduces breakdown risks and supports safe operation, forming the foundation of generator maintenance tips.

Checking and Changing the Oil

Oil lubricates the engine and regulates temperature. Neglecting oil changes leads to friction, overheating, and engine failure. Follow your owner’s manual for recommended viscosity and intervals. Warm the oil before draining to remove contaminants. Drain old oil into a sealable container, replace the filter, and refill with fresh oil. Run the generator briefly, check for leaks, and top up if necessary. Dispose of used oil responsibly.

Air Filter Maintenance

Clean air supports efficient combustion. Clogged filters reduce airflow, forcing the engine to work harder. Inspect monthly, especially in dusty conditions. Replace or wash reusable filters according to manufacturer guidelines. Ensure proper seating to prevent unfiltered air bypass. Adhering to these generator maintenance tips enhances engine efficiency and prolongs filter life.

Fuel System Maintenance

Fuel drives generator operation. Stale fuel causes clogs, varnish, and poor starts. Diesel generators require drained water separators and replaced filters. Inspect valves and supply lines for leaks or corrosion. Use fuel stabilizers if idle for long periods. Run the generator under load every three to six months to circulate fresh fuel. Proper fuel system care improves readiness and prevents unexpected repairs.

Battery Care

The battery ensures reliable starts. Monthly, inspect terminals and connections for cleanliness and security. Remove corrosion with a wire brush and baking soda solution. Test voltage between 12.4 and 12.7 volts. Recharge if below 12.0 volts. Check cases for damage. Use a maintenance-free battery for best performance and store the generator in a cool, dry area. Following these generator maintenance tips guarantees prompt starts during outages.

Cooling System Check

Maintain a stable operating temperature to prevent engine damage. Check coolant levels and hoses for leaks or cracks. Top up with recommended antifreeze, ensuring the engine is cool. Clean radiator fins gently. Annually, perform a pressure test to detect hidden leaks. Replace worn hoses and gaskets. Proper cooling system maintenance protects engine integrity and prevents downtime.

Electrical Components Testing

Generators rely on switches, relays, breakers, and wiring. Small faults can prevent power transfer or cause hazards. Test transfer switches regularly. Run monthly self-tests to monitor sensors and gauges. Inspect panels for error codes. Exercise breakers and relays manually to ensure smooth operation. Track electrical irregularities in your maintenance log. Applying these generator maintenance tips ensures safe, uninterrupted performance.

Load Bank Testing

Load bank testing simulates real power demands. Running the generator under light load is insufficient. Apply staged electrical resistance to test performance. Conduct tests annually or after repairs. Monitor voltage, temperature, and fuel consumption. Verify the unit can sustain full capacity for at least two hours. Document results to schedule preventive maintenance and avoid failures during outages.

Frequently Asked Questions

How often should I schedule professional maintenance for my generator?

Professional maintenance is recommended at least annually. Severe usage or harsh conditions may require biannual check-ups to ensure optimal performance and detect potential issues early.

Can I perform generator maintenance myself, or do I need a technician?

Routine tasks like oil changes and visual inspections can be done by knowledgeable homeowners. Complex diagnostics, load testing, and transfer switch servicing should be handled by certified technicians.

What type of oil should I use for my generator?

Use the oil grade specified in the generator manual. Correct oil prevents increased wear, overheating, and reduced efficiency.

How do I prevent fuel from going bad during periods of inactivity?

Use a fuel stabilizer and run the generator for at least 30 minutes every three months. Store fuel in approved containers in cool, dry areas.

Why is load bank testing important for generator health?

Load bank testing applies realistic electrical loads to verify rated capacity. It reveals issues missed by light-load tests, ensuring readiness during outages.

Ensuring Longevity and Reliability

Combine inspections, scheduled servicing, and proactive replacements for a resilient backup system. Keep detailed logs of maintenance activities, parts replaced, and unusual observations. Set reminders to avoid missed tasks. Building relationships with qualified technicians experienced in generator installation for homes MD ensures professional support. Annual professional tune-ups complement routine care and catch issues early. The cost of regular maintenance is minimal compared to emergency repairs. Implementing these generator maintenance tips guarantees reliable power. Explore our electrical services in Baltimore or review all our services. For personalized guidance, contact us via our contact page today.